Our graphic design team is dedicated to helping each client with their packaging project, and help them better connect with the customers they’re trying to reach. If you have an artwork of your own or previously created work from an existing marketing agency, be sure to send it to us in an .AI format. Clients are asked to carefully select their preferred fonts and Pantone colors so we’re able to bring your design vision to life. Once design is complete, clients are supplied with a digital or hard copy proof. Upon receipt of your approval, the final artwork is converted into a production-ready file that we use to create printing plates (Cliché).

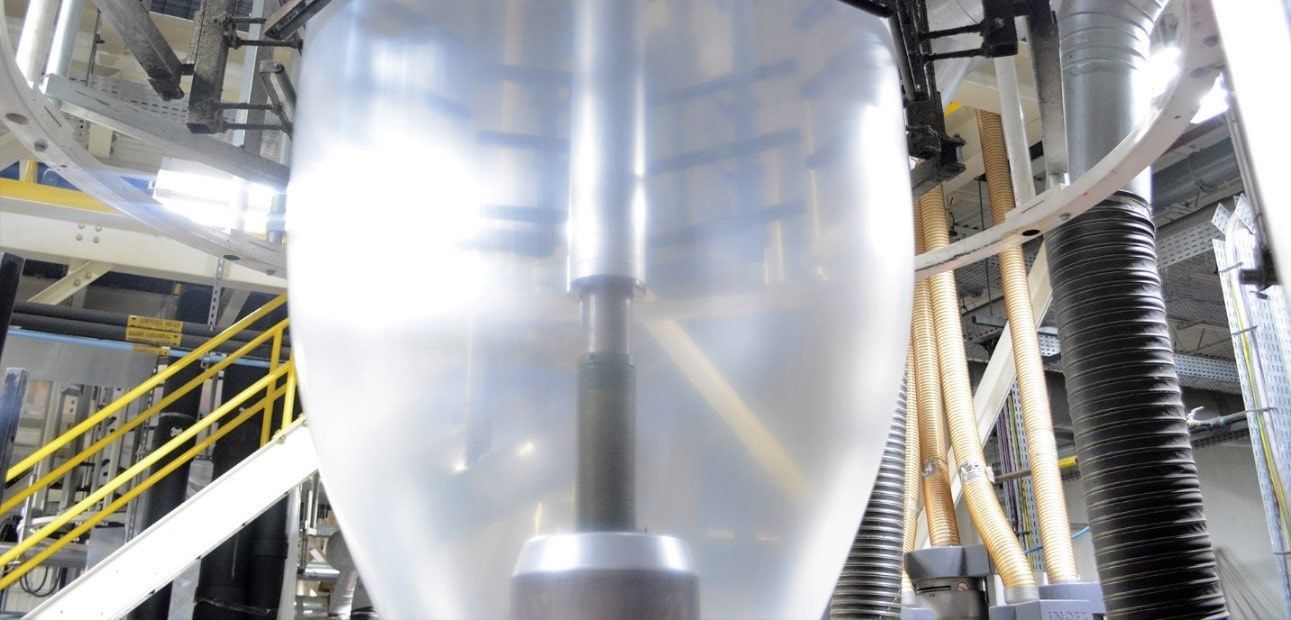

During this process, we melt the highest quality food-grade Polyethylene down before they’re blown into a cylindrical bubble. As the plastic cools, it is formed into a master roll of film before transferring it to our printing presses. We offer Biodegradable and Non-biodegradable film in many colors and thicknesses complemented by a variety of options, including anti-slip, anti-block and anti-static additives

Once the film for your project has been extruded into rolls, it is directed into our printing queue. Using a special mounting system, the plates produced from your design will be placed onto printing sleeves. Our facilities offer multiple printing presses and the capability to produce six-color, full process high-quality printing.

After printing your rolls, they are sent to one of the bag converting machines for processing. Once converted, the bags will be boxed and ready for shipping. Our facilities offer a wide range of bag converting machines that can be used depending on our clients needs and preferences. Our Plant features a facility that houses an arsenal of bagging equipment and design technology that includes wicketers, zipper machines, side and bottom seal, and perforation equipment. Contact us today to learn more about our offerings!

© Cloud Systems - 2021 | All Right Reserved.